Text Jos Wassink

Can commercial shipping benefit from auxiliary wind propulsion? The multidisciplinary research programme Wind Assisted Ship Propulsion (Wasp) will spend the next four years finding out how much fuel can be saved by making optimal use of wind.

The oldest depictions of sailing cargo ships date as far back as ancient Egypt. For at least 5,000 years, sailors have been using wind. Over time, sailing ships became larger, faster and more imposing, with the late nineteenth century clippers as the provisional highlight.

Steam engines and internal combustion engines took over propulsion around the beginning of the twentieth century. This went well for a long time. So well, in fact, that 90% of the things you see around you arrived by boat. Meanwhile, emission restrictions and air quality requirements are constricting this mass transport and a new chapter is emerging. Forward-looking minds are looking back to wind propulsion to reduce ship engine emissions. Like the old days, but different.

That is where WASP comes in. It involves two faculties: Aerospace Engineering (AE) for its knowledge of aerodynamics and measurements in the wind tunnel, and Mechanical Engineering (ME) for its knowledge of the design of ships, hydromechanics and the possibility of doing tests in the tow tank.

Another support sail technology, the eConowind, won the 2020 maritime innovation award. With two masts in a 40-foot container, the eConowind looks like the ultimate retrofit.

© Conoship

Practical slant

WASP was initiated in 2020 by retired TU Delft marine engineer Lex Keuning, who passed away in November 2023. It has a practical slant. The sailing facility should not require additional personnel on board and should deliver significant savings in fuel consumption. How much and how, is the question.

Lex Keuning 1950 – 2023

Lex Keuning passed away on November 28, 2023. He was at the forefront of important innovations in shipbuilding. Upon his retirement from TU Delft in 2015, he was appointed Knight in the Order of the Netherlands Lion. In 2021 he received the Maritime Designer Award for his idea for additional propulsion using wind energy.

“We do not want canvas sails anymore,” says Professor Bendiks Jan Boersma, leader of the WASP programme at the Maritime Transport Engineering group (ME). He is referring to the large kites on the bow of some cargo ships (SkySails) and the majestic DynaRig sails. The TU Delft research mainly focuses on rotating cylinders, the so-called Flettner rotor, which, thanks to an aerodynamic effect, exert a propulsive force on ships. According to Programme Manager Dr Albert Rijkens, the choice is evident: rotary cylinders are best fitted to conventional ships without requiring additional personnel or knowledge. Previous research, says Boersma, showed that the application of such a rotor can save 5% to 15% fuel. The goal of the WASP programme is to arrive at a design of hull and ‘sail’ (or pillar) that saves a significant percentage of fuel. The research will require the efforts of 16 graduate students, 8 doctoral students and 4 postdocs over the next four years under the direction of four staff members divided between the two faculties. The cost of the programme, EUR 4 million, is covered by Dr Lex Keuning’s Bijlboeg (axe bow) Fund.

‘A significant saving in fuel’

Magnuseffect

What is the secret of the top spin in tennis? The top of the ball rotates around a horizontal axis against the direction of motion. What happens? The ball hits the ground much sooner than you expect. A backspin, on the other hand, keeps the ball in the air longer. The nineteenth century German physicist Heinrich Gustav Magnus came up with an explanation: rotation in the direction of the wind (under the ball) causes a locally higher wind speed and therefore a low pressure. On the top, the opposite happens. The net effect is a force perpendicular to the direction of flow toward the side rotating with the direction of flow. A rotating cylinder on a ship’s deck in the wind experiences a force perpendicular to the wind direction in addition to resistance due to the Magnus effect. When the wind comes from the side, if the cylinder is vertical and rotates in the correct direction, it is a forward moving force. The German engineer Anton Flettner developed a rotor sail, known as the Flettner rotor, about 100 years ago based on this.

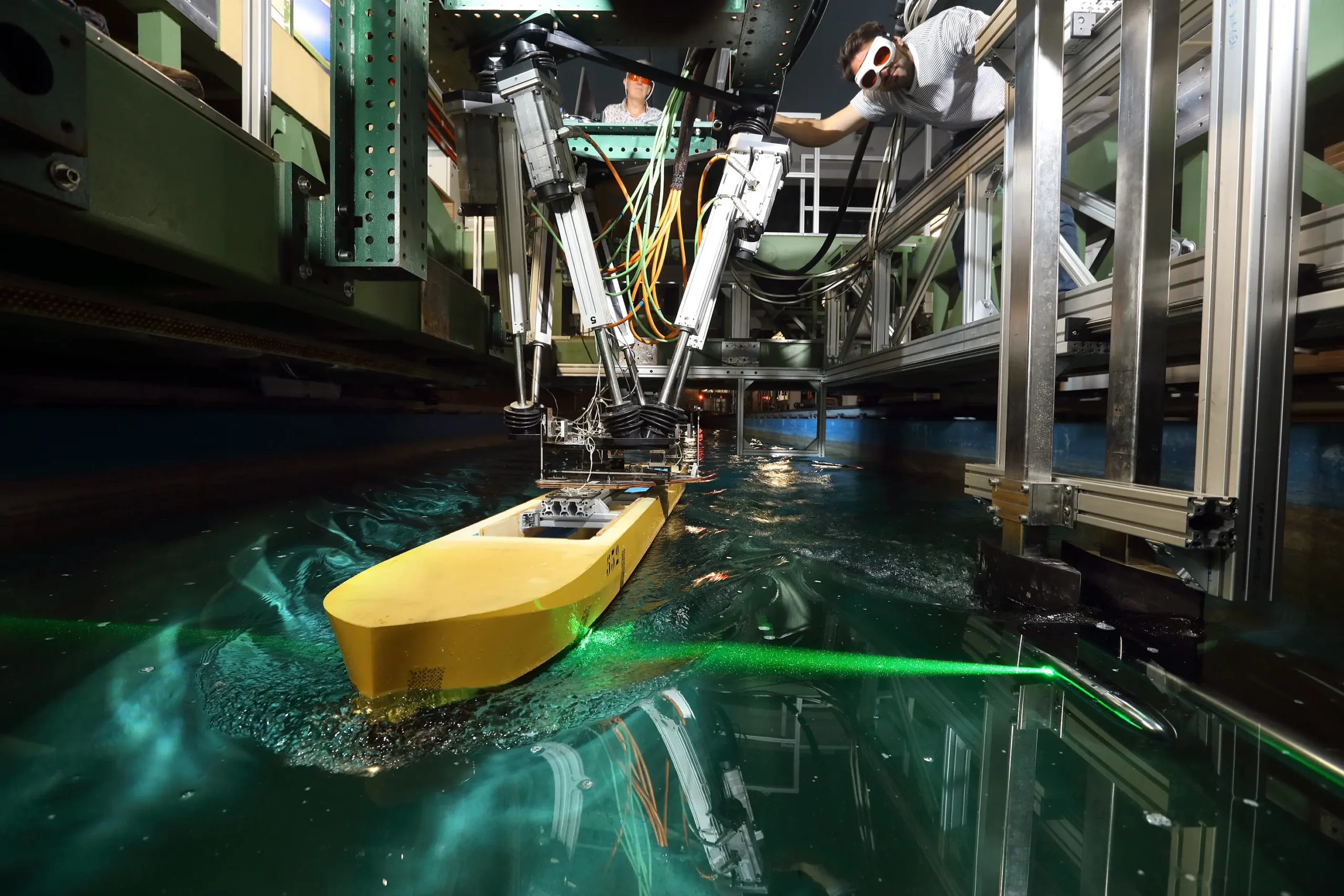

In the tow tank, researcher Gunnar Jacobi measures the effect of keels and bilges on the hull. In the background, technician Peter Poot operates the measurement platform.

© Sam Rentmeester

Back from gone

Sail support for cargo ships goes back to the 1980s, when Keuning researched it under the guidance of Professor J.Gerritsma. Back then, the oil crisis was the trigger.

Now reducing emissions from ships is the main reason. “That has become a much more important issue than the price of oil,” Keuning observed. “Only, scientific research is still getting off the ground very slowly.”

So Keuning took the initiative himself and submitted the ‘Wind assisted ship propulsion research’ proposal in October 2020, with the accompanying funding of EUR 4 million from his own fund. “Fuel prices, emission restrictions and dependence on international logistics – it’s all in flux now. So if you want to do something to make shipping more sustainable, now is the time,” said Keuning.

“The development of wind-assisted propulsion requires an integrated approach from TU Delft and industry. Shipyards have to work on it, shipping companies have to want it, but TU Delft has to lead the way in developing the knowledge and tools. If 10 years ago you would have said that by 2023 serious thought and discussion would be given to wind propulsion on cargo ships, you would have been put away in a mental hospital. So things are really changing.”

‘A rotor can take over perfectly’

Flettner rotor on the quay. This most industrial form of sailing is almost 100 years old.

© Norsepower

Flettner rotor model in the wind tunnel of the University of Technology in Milan.

© Giovanni Bordogna

Research agenda

In the wind tunnel, the question is how to minimise the resistance or drag of the rotor while maximizing the lift generated (perpendicular to the wind direction). Former PhD students Giovanni Bordogna and Nico van der Kolk made a start on this and started their Blue Wasp Marine company after their PhD in 2020. New research in the wind tunnel should show whether a rotor with multiple sections rotating at different speeds produces a better effect than a one-piece rotor.

Underwater, the force on the rotors must be converted into forward motion. Sailing yachts have a keel or daggerboard to counteract the lateral pressure so that it is mainly the forward force that remains. But how is this best done on a freighter? Experiments in the tow tank should clarify the currents around a freighter.

When asked what he expects from the research, Keuning does not just talk about efficiencies or CO2 emissions, but about mental shifts. “For me, the research will be successful among staff and students at TU Delft if interest in wind propulsion on cargo ships seriously grows.” Furthermore, he hopes that industry will pick up and adopt the results. In terms of the most promising applications, he sees tankers with large flat decks, passenger ships – partly for the ecological appearance – naval vessels and coast guard ships that spend much of the day sailing slowly. “A rotor like that, then, can take over perfectly.”

Bijlboeg fund

Good inventions are rewarded. In the 1990s, Lex Keuning sought a solution for fast sailing ships that suffered from the blows of waves. His solution: a longer hull with a straight bow, the axe bow or bijlboeg, which extends aft into a wider V-shape.

The bow cuts through the waves and barely rises out of the water. The bijlboeg was patented in 2007 by TU Delft as owner and Keuning as inventor. Keuning, his department and the Executive Board are equal shareholders. Shipbuilders who use this hull shape must pay EUR 25,000 for the rights.

That same year Keuning made a remarkable proposal: he offered to renounce his share if the department and TU Delft would do the same. Furthermore, shipbuilder Damen offered to double the price per right issued as the first licence owner. All involved agreed, and so in 2007 the Bijlboeg Fund for maritime research was established in the form of a shielded account at Damen under the control of the Executive Board.

Nearly 10 years later, in 2016, the Tax Office advised that the savings pot was becoming too big. That is when those involved (Keuning, the Executive Board and Damen) established the Bijlboeg Fund. This foundation managed about EUR 10 million before the WASP programme started.

Almost half of that was used for research into wind support on cargo ships. The axe bow patent runs until 2027. What will happen thereafter is still open as the fund will not be empty by then. ‘Chances are’, Keuning writes, ‘that the unique cooperation between the company (Damen) and the university (TU Delft) will be continued in one way or another by both.’

The oil tanker Maersk Pelican tested two rotors for a year and reported 8.2 percent fuel savings.

© Norsepower

‘If you want to make shipping more sustainable, now is the time’

Read more about Delft research to wind-supporting ship propulsion: ‘Will sails of steel make ships more sustainable?’ on delta.tudelft.nl.