Tech & Innovation Kitepower

Everything at Kitepower revolves around that kite in the distance. It is a product of intuition and of science. How do design and research complement each other?

The Vader Piet wind farm on the windy southeast corner of Aruba is sacred ground for wind energy experts. The park was an initiative of wind energy pioneer Henk Hutting (1952-2021) to make the island’s energy supply more sustainable. Hutting also supported Kitepower from the start, so it was no coincidence that Kitepower landed here for a demo to the Ministry of Defense. The army wants to reduce energy dependence and CO₂ emissions on missions. Electricity from kites seems to be a nice alternative, especially on a windy island. The Ministry of Defense wants to test kite energy for employability and continuity.

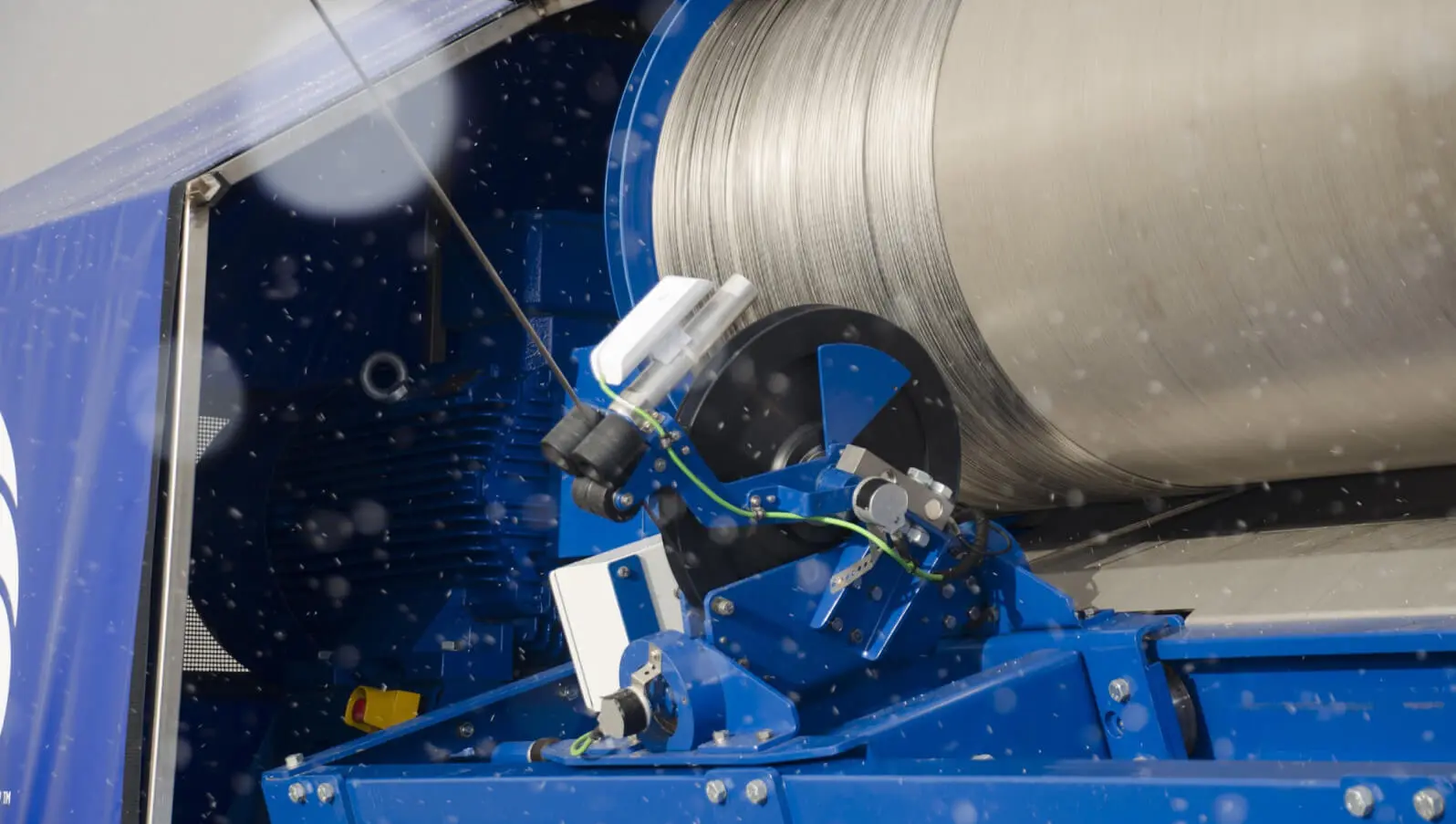

Kitepower, alongside the solar car Nuna, is one of astronaut and Professor Wubbo Ockels’ (1946-2014) dream projects that took off quite well. After three successful deployments and nine improved versions of the kite, the TU Delft start-up declared itself ready for the next phase: bringing its first 100 kilowatt mobile kite power unit to market. The crowdfunding launched for that goal in August has now raised EUR 900,000 – EUR 200,000 more than requested. Inside Kitepower’s workshop in the old cable factory on Schieweg, one can see just how immense the kite actually is. Kite designer Bryan van Ostheim (35) talks about 60 square metres – the wall of a sports hall. Folded up, the kite is not much bigger than a bungalow tent and weighs 60 kilograms. Today the weather is calm, which is why people are working here in the hall, or upstairs in the offices. From wind force five, the office empties. Then the call of the sea becomes irresistible. That is when you’ll find the staff on Scheveningen beach where they fly over the waves as kite surfers.

It was destined to be. Grandpa Van Ostheim built huge kites with paper and bamboo. Bryan’s father did adjustment and alteration work for a kite shop in Hoogeveen, and Bryan himself discovered kite hopping in a meadow there. “We got carried away by the power of the wind and occasionally made high jumps,” he says. No wonder Van Ostheim eventually found his calling as a kite designer – apparently a profession with fewer than 20 professional practitioners worldwide. Dr Roland Schmehl, a researcher at the Faculty of Aerospace Engineering, was one of Kitepower‘s founders in 2014, along with the current CEO Johannes Peschel.

From wind force five, you’ll find the staff on Scheveningen beach

Schmehl had come to TU Delft to explore the possibilities of power generation with kites: airborne wind energy. After founding the company, Schmehl chose to stay involved in teaching and research at TU Delft. “Kitepower is our outdoor laboratory,” he explains. “They run all the experiments for us. They run tests, they fly and collect data that we use in our research. In return, they get information from us on how they can further improve their kites. That’s our interaction. It’s a very nice cycle.” Van Ostheim’s claim to fame was a light wind kite for kitesurfing. The trailing edge was a single layer to save weight. But the leading edge (the nose) was inflated, making it easy for the kite to come back off the water. “I made a small six square metre prototype and it worked immediately. The KiteMobile platform made a video of it which generated publicity.

That’s how Kitepower spotted Bryan van Ostheim and they invited him to join them. Later, they were joined by Pepijn Smit, who had learned the kite making craft in New Zealand from Peter Lynn – a legend in the kite community. “I was uncertain about it at first,” Van Ostheim recalls. “I thought that I would then be among all these TU Delft boffins and I wasn’t sure how I would deal with that. But the collaboration went really well. You just have to make sure you complement each other and listen well to each other. A system like this is real teamwork. Everyone does what he or she is best at.”

Challenging problem

“You can make a good kite design that gets to about 80% of the ideal using an intuitive and qualitative approach,” Schmehl states. “But for the remaining 20%, you really need to use quantitative methods. These let you significantly increase the power. Another aspect to consider is the ‘de-power’ behaviour of a kite like this. If you release the steering lines, the kite aligns with the wind, minimising the force on the tether. But what exactly happens with the wing is still a bit of a mystery. As the kite is a three-dimensional object with a C-shaped curvature and a three-dimensional line system, you need a good computer model to optimise it.” “There are plenty of cameras in the kite, so when we fly we can watch live,” Van Ostheim says. “That‘s very valuable. A kite like that is full of markings and attachment points, so you can trace any deformation back to a precise position. You can then try to reproduce the deformation in the simulation so that you can correct it. The deformations make kite simulations very difficult. The kite’s shape can be aerodynamically perfect on the computer, but if it doesn’t look right in the air you still have to start changing things.” “Including deformations in your calculations is the basis of kite simulations,” Schmehl responds. “I call that a fluid factor interaction problem. The shape of the wing affects the aerodynamics around the wing and this distributes pressure on the wing. That in turn affects the shape. There is a cycle of shape that affects force that affects shape. So you have to solve shape and force simultaneously and that is one of the most challenging problems we have here at the Faculty.” Thus, the research continues unabated, as do the optimisations and the scaling up. In the coming years, Kitepower will work on scaling up to kites of 200, 300 and 500 kW.

More information: thekitepower.com