Chips have become an indispensable part of modernday society, powering everything from smartphones, televisions, cameras and refrigerators to ovens, cars, electric bikes, medical imaging equipment, solar panel systems and credit cards. Heavy investment has seen the Netherlands climb to the apex of high-end chip technology, thanks in no small part to universities and knowledge institutions with their specialist knowledge and labs. The three universities of technology (Delft, Eindhoven, Twente) have specialised in fundamental research and innovation testing, with Delft’s scientists focusing primarily on the former.

According to Dr Pieter Telleman and Professor Kofi Makinwa, the applications of chips are only set to increase going forward. Both work at TU Delft, Makinwa as head of the Microelectronics Department (Faculty of Electrical Engineering, Mathematics and Computer Science) and Telleman as head of campus clean rooms. Focusing on chip design and production, the Mechanical Engineering and Applied Science faculties work on developing new materials and production techniques for the chip industry, making the university a key player on the world stage of chip technology.

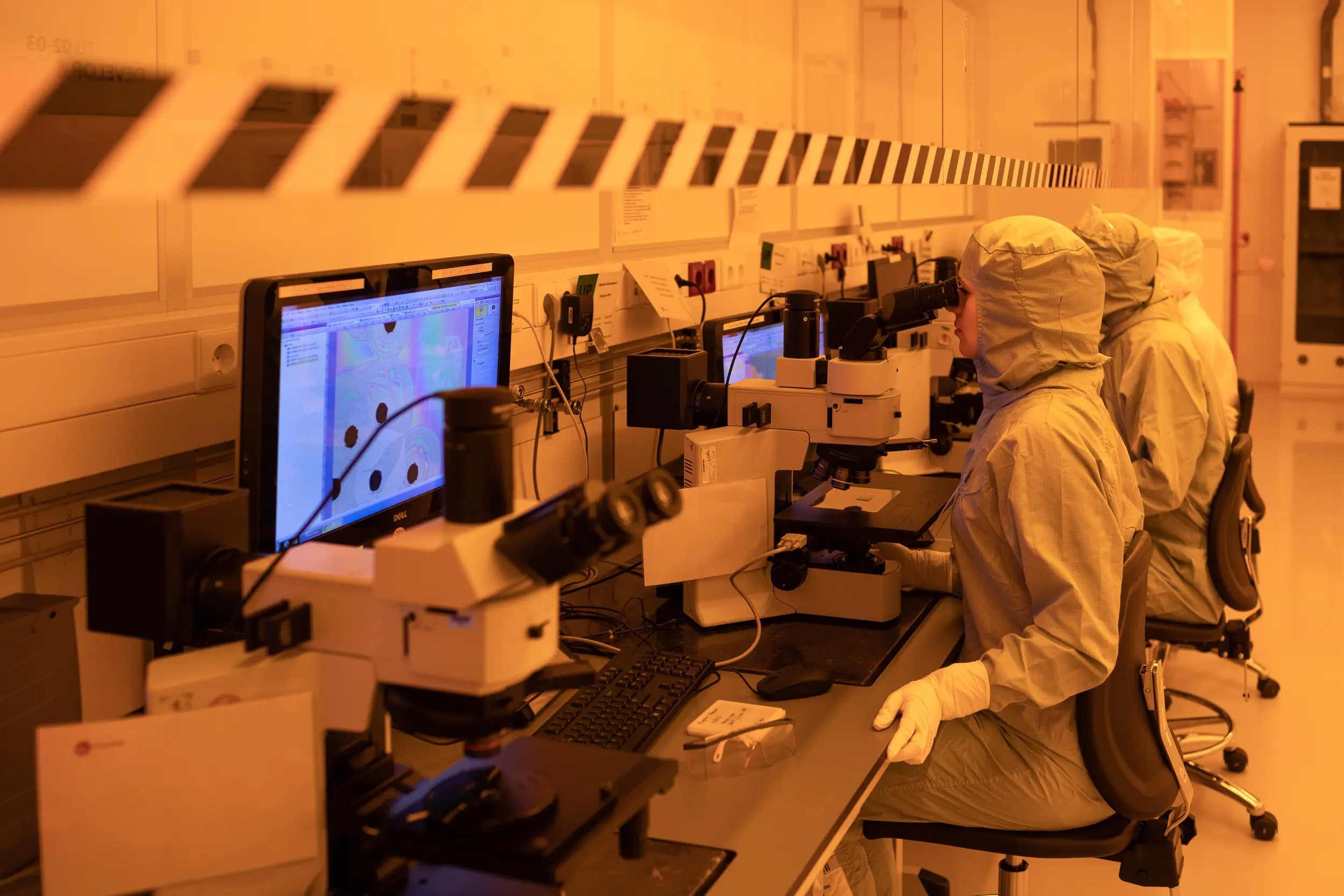

Researchers in the Kavli Nanolab.

© Marieke de Lorijn

Chip production in clean rooms

Today’s chips can consist of billions and billions of transistors. The initial design – a mask of sorts – is made on a computer, before being laid on a thin, round wafer of silicon coated with a photosensitive layer in a clean room. This photographic process removes part of the mask, and layers of gold, aluminium or silicon are applied to the wafer to create a functioning chip. TU Delft’s clean rooms are capable of manufacturing chips with an accuracy of one-thousandth of a millimetre, the size of a bacterium. A single wafer yields tens of thousands of chips ranging in size from 1 mm2 to 1 cm2. Clean rooms are equipped with powerful air filters and overpressure systems to make them entirely dust-free, as well as being virtually vibration-free and protected against EM radiation to avoid production disruptions.

NanoLabNL collaboration

TU Delft has two cleanrooms for the manufacture of microchips. While the Kavli Nanolab is primarily intended for fundamental research, the Else Kooi Lab is more focused on product development. Telleman explains how Dutch and international academics and companies have flocked to Delft for research and product development projects in these state-of-the-art labs. “The companies working there run the gamut from industry behemoths such as ASML to start-ups run by ex-TU Delft researchers.

As NanoLabNL, we work closely with the clean rooms of the universities of Twente, Amsterdam, Groningen and Eindhoven, since the construction and maintenance of cleanrooms is very expensive. By coordinating which university does what, we can reach a higher level together. One main problem is that our research is too dependent on the influx of bright minds from abroad, which conflicts with our commitment to knowledge security.” Telleman stresses that technology is essential for the Dutch economy. “Unfortunately, labour shortages are becoming an increasingly tricky constraint, partly due to restrictions on the inflow of non-EU workers, which affects our ability to harness research and innovation to address key societal issues.”

Dutch and international academics and companies flock to Delft’s state-of-the art clean rooms for research

In rooms where photolithography is used, the light is yellow because that process is sensitive to UV and blue light.

© Marieke de Lorijn

Dr Gerard Verbiest does chip research with sound waves (photo for illustration, he does not appear in the story).

© TU Delft/Studio Wavy

Delft and quantum technology

Quantum technology is an important research interest at Delft. All around the world, scientists – spearheaded by Delft – are working on a quantum computer, which is expected to perform computations at breakneck pace. This awe-inspiring computing power can be particularly valuable in figuring out complicated weather forecasts or calculating traffic flows, for example. Rather than the transistors of traditional computers, quantum computers harness the quantum properties of elementary particles such as atoms, electrons or photons. Partly thanks to investments by the National Growth Fund in Quantum Delta NL – a national centre based in Delft – the Netherlands has become a world player in quantum technology, says Telleman: “Several start-ups are already working on ways to commercialise the quantum effect on chips. Developing these chips, however, is a mammoth task, if only because they only work at temperatures close to absolute zero, or -273° C.”

Cheaper and more accessible

In addition to working on quantum technology, Telleman and Makinwa stress that the development of transistor chips is also forging full steam ahead. As an example, Makinwa cites wireless communications, whose applications are growing all the time. “Take WiFi and Bluetooth, for example. You can use virtually the same technology to make radar systems for cars, for example. The main drawback is that all that wireless communication uses a lot of energy, already amounting to several percent of global energy consumption. That’s why we’re trying to build considerably more economical chip systems.”

Makinwa’s research revolves around microsensors that can detect and measure the physical and chemical properties of their environment. The applications of such chips are manifold, with manufacturers using them them to monitor production processes. Alternatively, cars can use them to monitor tyre pressure or battery power consumption, while weather stations equipped with microsensors can measure temperature, air pressure, humidity and wind speeds. According to Makinwa, who was born in Ghana, countries all over the world can benefit from wireless communication and microsensors. “Weather stations are obviously very important for developing countries, and mobile phone use has also boomed there, with the average modern-day smartphone boasting some 20 sensors. Instead of laying cables to each and every house, all you have to do is put up base stations to connect even the most remote villages.

‘You can use these chips to speed up the development of new medication, while cutting costs and eliminating animal testing’

Using the Estrellas Deep trench ICP etcher, through wafer vias are made at the Kavli Nanolab. Vias are holes 50-100 micrometres wide right through a 500 micrometre wafer (thin sheet of silicon).

© Marieke de Lorijn

Chips that mimic the brain

In 2018, Innatera was founded as a spin-off from TU Delft that specialises in developing and producing neuromorphic chips. These chips mimic how the brain works, says Director Sumeet Kumar, who originally obtained his PhD at TU Delft on the design of energy-efficient microprocessors. “They recognise patterns the same way our brains do, which is made possible by their highly unconventional chip architecture. Apart from using the binary system of zeros and ones, they also manipulate electrical currents, enabling them to process data one hundred times faster than standard chips, using only one-fifth of the power. As such, they’re an important milestone in our pursuit of a greener planet!” These so-called Spiking Neural Processors are useful for applications such as sound recognition in headphones, radar sensors in video doorbells and image recognition in security systems, which are all powered by very small batteries.

Sample holder with chip.

© TU Delft/Studio Wavy

Inverters for the quantum Internet

QphoX is one of the companies using TU Delft’s clean rooms, in this case the Kavli Nanolab. This Delft spinoff develops and builds quantum inverters, which can convert quantum information in the form of microwaves (which quantum computers use) into light waves. Optical signals can travel much greater distances in glass fibre than microwaves, which is a significant challenge, says director, co-founder and professor of Quantum Physics Simon Gröblacher, because the frequencies of the two domains differ by a factor of 100,000. “We’re trying to solve this issue with a mechanical oscillator, an inverter that turns microwaves into optical frequencies, using special chips. The goal is for quantum computers to communicate with each other via an optical network, ultimately paving the way to a quantum Internet. We’ve even used our chips to develop a quantum modem!”

Bioelectronics

Another special area of interest of Delft’s Microelectronics Department is bioelectronics, a field of research that aims to pick up, process and reproduce the electrical signals that drive the human body. Signal transmission defects, such as in spinal cord injury, Parkinson’s disease or epilepsy, could then be fixed with the help of chips. Makinwa: “We’re also working on so-called organs-on-a-chip, which consist of an artificial organ, made of heart, liver lung or kidney tissue, in a liquid. You can use these chips to speed up the development of new medication while cutting costs and eliminating animal testing. You could even create an organ-on-a-chip with cells – tumour cells, for example – harvested from a specific patient to see which drug is most effective, essentially paving the way for personalised medicine.”

Adaptive AI chips

Although microchip development is moving at lightning speed, there are still many challenges ahead, say Telleman and Makinwa, including the development of heterogeneous chips that integrate different systems, such as microelectronics, micro-optics and quantum technology.

‘I do worry whether the Netherlands will continue to invest in chip technology’

And then there’s AI chips with adaptive neural networks that respond to their environment while learning, or non-silicon chips made from new materials such as polymers with other functionalities. Unlike silicon, these chips can be made flexible and unlock all sorts of novel measurements, e.g. as biocompatible sensors in muscles or the bloodstream. Telleman: “Chip R&D costs a lot of money. Fortunately, the EU’s European Chips Act came into force last year in a bid to build a European chip industry, allocating EUR 15.8 billion for this purpose until 2030. Judging from recent developments, however, I do worry whether the Netherlands will continue to invest in chip technology to hold onto its position as a world leader.”

Interested in this subject? Discover TU Delft’s Learning for Life courses that support professionals throughout their careers, including a course on microchips.