Text Jos Wassink

© Illustration Stephan Timmers

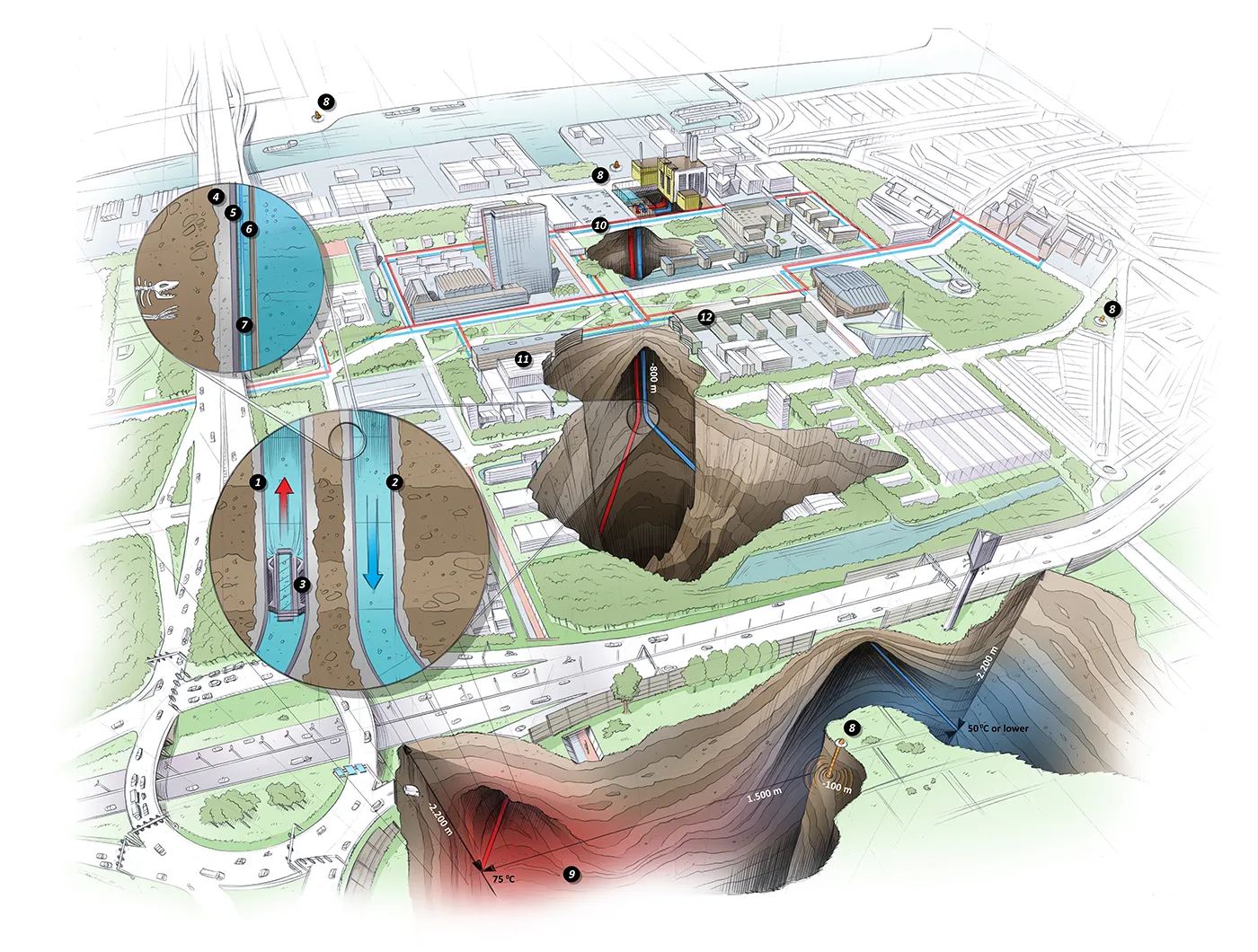

A huge heat storage facility will be built under the Delft campus. The reservoir will be able to hold 500,000 cubic metres of hot water and will supplement the existing Delft geothermal energy well. This heat storage system will be one of the largest in Europe.

Although rather inconspicuous and, at 200 metres, not very deep, the five wells being drilled on the Delft campus are special. Together they form the access to a huge amount of hot water underground. Energy storage expert Dr.ir. Martin Bloemendal from the Faculty of Civil Engineering and Geosciences (CiTG) calculated that the 500,000 cubic metres of hot water could fill the EWI tower about three times over. The campus’ hightemperature aquifer thermal energy system will be one of the largest, most complex and most intensively measured thermal storage systems in Europe.

Despite its unobtrusiveness, it is envisioned to become a unique infrastructure for demonstration, education and research. For example, research is now being conducted into how to convert a conventional heat grid into a future-proof, fossil-free heat grid.

The underground thermal energy storage supplements the Delft geothermal energy well, for which drilling began in late 2023. It pumps up hot water at temperatures between 75-80°C from two kilometres deep at an approximate rate of 350 cubic metres per hour. An equal amount of cooled water is then reinjected via another well. A geothermal well works best with constant heat production, but the demand for heat is anything but constant and very season-dependent.

Drilling during the summer of 2023.

© Thijs van Reeuwijk

Between layers of clay

Surplus hot water not needed for heating between April and October will be stored underground. This will then become a reserve supply for the winter period when heat demand (red in the drawing opposite) exceeds the supply from the geothermal source (green). The hot water forms a 60-metre-high ‘hatbox’ layer in a subsurface aquifer between two clay layers at depths of 120 and 180 metres, and has a diameter of 120 metres. The storage system consists of two hot wells at 80°C and three warm wells at 50°C. In winter, the system supplies heat to the heating grids of the campus and Delft municipality by pumping water through a heat exchanger from the hot well to the warm well. In summer, the flow direction between the hot and warm wells reverses, filling the hot reservoir with heat from the deep geothermal source. During this process, the temperature can sometimes be increased to 90°C using a heat pump when the electricity rates are low.

Put on a jumper

Calculations show that geothermal energy can provide 90% of the heating requirements of the campus and connected neighbourhoods. Direct geothermal covers 60% of demand, while high-temperature underground storage contributes another 30%. Spikes in heat demand account for 10% of the total and are covered by natural gas boilers in the cogeneration plant. “We’re opting for that now,” says Bloemendal, “because those boilers are already there. When building a new system, things would be done differently. Or you could just put on a jumper during those few cold days.” Necessity is the mother of invention Underground hot water storage is not a new concept. The first projects in the Netherlands emerged after a few energy crises. The Western world had to deal with an oil boycott in 1973 and gas supply disruptions from the Soviet Union in the 1980s.

Energy prices soared and researchers started looking for alternative heat sources. Innovative minds thought it should be possible to store summer heat underground for use in winter. In 1985, Groningen’s Beijum district received high-temperature solar heat storage and Utrecht University stored heat from its own cogeneration plant (1991), as did a health centre in Zwammerdam. But not everything was a success. According to the report State of the Art HT-ATES in the Netherlands by Heatstore (a consortium of research institutes and private companies from nine European countries), less than half of the stored heat was returned, and when energy prices fell, heat storage was often no longer profitable. Only the hightemperature heat storage facility in Beijum is currently in operation.

Timelapse Geothermie Delft drilling phase

© Polycentric Solutions

Gas extraction

Although it was never the intention, TU Delft is becoming a supplier of natural gas. One cubic metre of natural gas is extracted for every cubic metre of water from the deep subsurface of geothermal wells, says professor of geothermal energy Phil Vardon (CiTG). He is leading the geothermal project on campus.

This means that TU Delft produces about 350 cubic metres of natural gas every hour. Letting it escape is not an option because it would pose a fire hazard and methane is a strong greenhouse gas. After consultation with stakeholders, it was decided to inject the gas into the existing gas pipeline for use elsewhere, thus making the Netherlands slightly less dependent on gas imports. At over two million cubic metres of gas a year, gas production is quite significant. It’s equivalent to the average use of 1,600 households and generates several million euros in revenue. Vardon: “The consortium that owns the geothermal project (TU Delft, Aardyn, Shell Geothermal, EBN, ed.) receives the revenue from the gas and the geothermal energy, which is offset against costs. The consortium is projected to make a limited profit overall, otherwise they would not invest. TU Delft’s share of those profits will benefit the university as a whole.”

Calculations show that geothermal energy can meet 90% of the heating needs of the campus and connected neighbourhoods

Uncertainties

The Delft project draws on past lessons. The large volume of 500,000 cubic metres is in line with Heatstore’s recommendations and older buildings on campus are sufficiently well-insulated so that 70°C input is enough for heating. Uncertainties mainly involve storage efficiency, underground spread of the hot groundwater, andmicrobial and chemical impacts. To eliminate these concerns, 10 boreholes are being made in the area to measure the temperature over the entire depth and a monitoring well has been drilled to test groundwater quality. There are always risks. Limescale and microbial films can clog pipes and the yield is uncertain.

Bloemendal expects initial returns of 40-50%. This could increase to 70-80% after a few years due to the warming of the subsurface and the decreased cooling. Ultimately, the mission is to develop and showcase high-temperature heat storage in an urban environment, including its control and integration into the energy system. It should demonstrate how a conventional heat grid can be converted to a future-proof, fossil-free heat grid. The underlying goal is to become independent of natural gas and to develop a (virtually) CO2-free heating system. This is a major undertaking when you consider that heating and cooling accounts for half of fossil energy consumption in Europe.

TU Delft offers several courses in geothermal energy. To view them, go to: online-learning.tudelft.nl

© Stephan Timmers

Geothermal Delft

After three months of working day and night, the two wells of the Delft geothermal well have been drilled. This 75°C geothermal energy source will be used to heat buildings on campus and in the surrounding area. Some 6,000 rental homes belonging to Delft housing corporations (including student housing provider Duwo) will be connected via a heat grid, and Inholland University of Applied Sciences also recently signed up.

What does it look like underground? The installation consists of an 1 intake pipe and a 2 discharge pipe that will drop 800 metres vertically from Leeghwaterstraat. At around 500 metres deep, a 3 pump will pump 300 cubic metres of water per hour – enough to fill twelve lorries. From a bend at 800 metres deep, the pipelines run off to different parts of the same hot water source located at a depth of 2.3 kilometres. At the surface, the intake (producer) has a temperature of about 75°C. The discharge (injector) has a temperature of 50°C. As the groundwater flows from the injector to the producer, it heats up again due to the geothermal energy. The pipes have a diameter of 50cm at the surface; at the bottom of the well, this is 10 to 15cm.

To prevent leaks due to corrosion from the hot and salty groundwater, the pipes are multi-layered: The outer wall 4 is made of cement, followed by a steel pipe 5 and an epoxy inner lining 6. There is a 7 fibre-optic cable in the water flow for measuring the temperature and pressure inside the pipe. Seismometers 8 are installed at four locations around the well at a depth of about 100 metres, which is enough to isolate them from surface activity. The measuring points register the structure of the subsurface via high-resolution seismic measurements. They also use electromagnetic measurements to detect differences in density, and thus the groundwater flow through the 9 reservoir. An installation to capture natural gas from the groundwater will be built on Leeghwaterstraat, next to the existing cogeneration plant. The hot groundwater will then be filtered and passed through a heat exchanger that will transfer the heat from the groundwater to the campus’ 10 heat grid at a temperature of 75°C. In older buildings ( 11 , 12 ), changes will have to be made to the heating systems since they are set to a higher input temperature. After passing through the heat exchanger, the temperature of the water is about 50°C.